WHO WE ARE

The Smart Apparel Exporter

since 2001

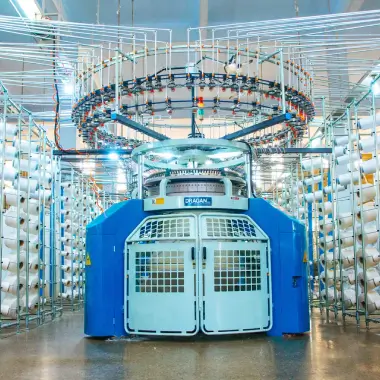

Knitpro Creations has been a pioneering force in the Apparel exports field. Over the years,

we have evolved and expanded forming a formidable group alongside JRP EXPORTS,

SRI DHANALAKSHMI EXPORTS and TEXPRO FASHIONS. Each entity within the group is skilfully managed by experienced partners. What sets us apart is not just our advanced machinery but also our commitment to ethical practices. All our companies are accredited with prestigious certifications such as SEDEX, OEKO-TEX, GOTS, BCI, GRS, BSI, FAIRTRADE and DISNEY FAMA.

We prioritize Sustainability, Quality and Ethical business practices.

- Trends the Current Market

- The rayon fabrics wholesaler

- The Global fabrics distributor